How Our Shade Sails Are Made

At Australian Custom Shade Sails, we take pride in crafting high-quality shade sails tailored to the unique needs of Australian homes and businesses. Our manufacturing process combines expert design, precision craftsmanship, and durable materials to ensure each shade sail offers superior UV protection and longevity.

Step 1: Design Consultation

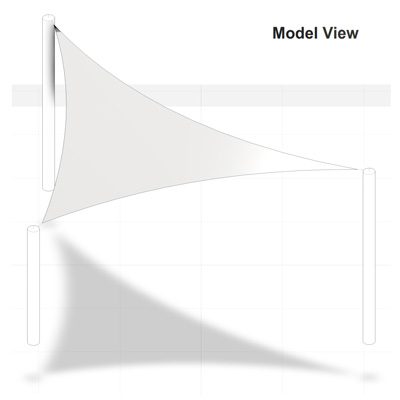

Each shade sail project starts with a tailored design consultation. Our team works closely with you to understand your goals—whether it’s sun protection, visual appeal, or site-specific challenges. We take into account the location, intended use, and overall aesthetic to ensure the finished product is both practical and visually seamless with its surroundings.

Step 2: Material Selection

We use high-performance fabrics engineered to withstand the harsh Australian climate. These materials offer superior UV protection while maintaining breathability, ensuring comfort and safety. Clients can choose from a range of colors and textures to match their design preferences.

Download the Rainbow Shade Z16 Colour Guide here.

Download the Rainbow Shade Extreme 32 Colour Guide here.

Step 3: Precision Cutting

With the design confirmed and materials selected, our skilled fabricators begin the cutting process using advanced, computer-guided plotting technology. This ensures every panel is shaped with absolute precision according to the exact specifications of the design.

Accurate cutting is essential not only for a perfect fit but also to maintain uniform tension across the entire sail once installed. This stage lays the foundation for the sail’s performance and longevity, ensuring it remains taut, stable, and visually clean in all weather conditions.

Step 4: Reinforcement and Stitching

To enhance durability, we reinforce the edges of the shade sail with robust webbing and employ double-stitched seams.

This meticulous attention to detail ensures the sail can withstand strong winds and prolonged exposure to the elements.

Step 5: Quality Assurance

Before delivery, each shade sail undergoes a thorough quality inspection. We check for material integrity, stitching consistency, and overall finish to ensure the product meets our high standards.Step 6: Delivery and Installation Support

After passing quality checks, the shade sail is carefully packaged and delivered to the client. We provide detailed installation guidelines and support to ensure the shade sail is installed correctly and functions as intended.